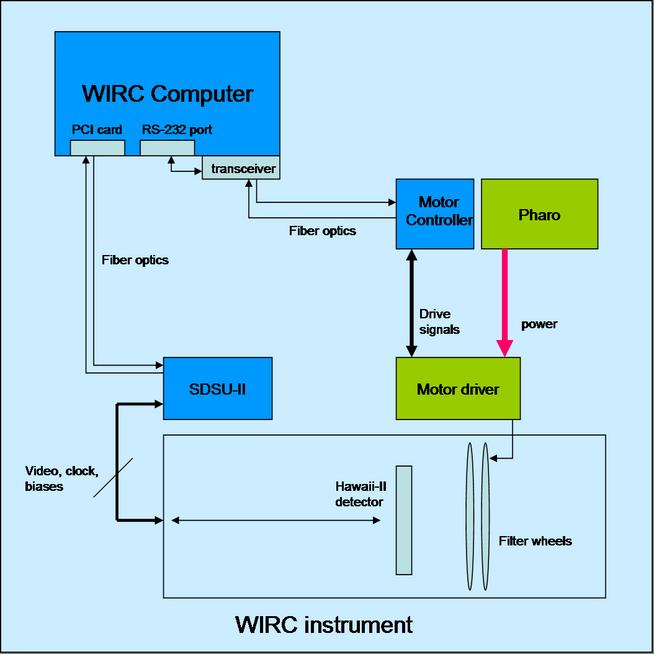

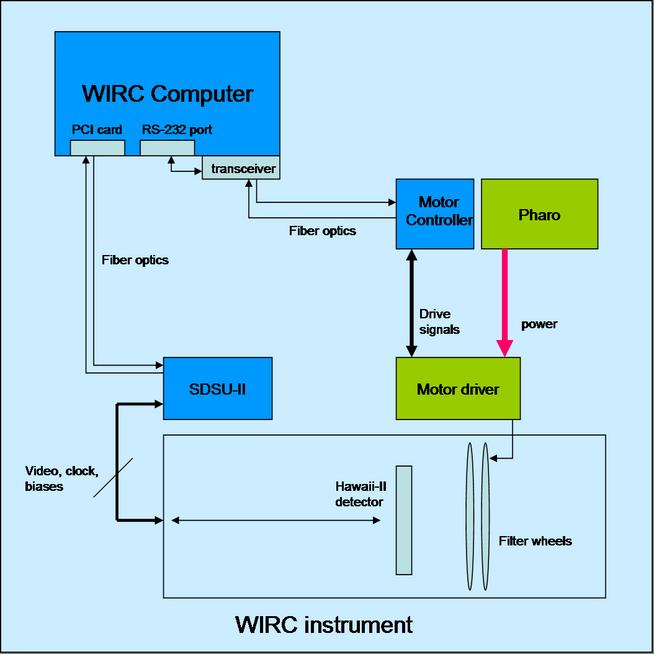

Fig 1: General Diagram

Fig 1: General Diagram

Detector Controller

As shown in figure 1, the communications between the Host computer and the controller electronics (SDSU-II controller) is done using a fiber optic link between a PCI card on the computer and the timing board card of the controller. All the image data, and command/response transactions are performed using this two-lines optical fiber (one receiver, one transmitter)

The controller is connected to the detector through

a set of external cables (4 videos, 1 Clock cable, 1 Bias cable)

Motor Controller

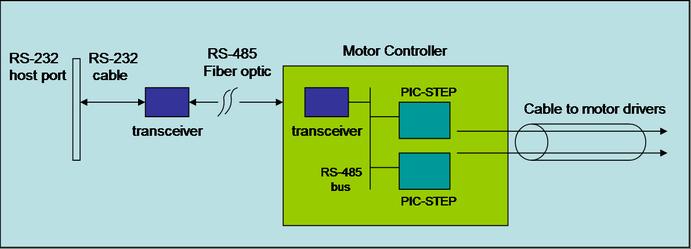

As shown in figure 1 and figure 2,

the communication with the motor controller box is done using the RS-485

protocol. The physical media used is fiber optic.

The little gray box on the back of the Host computer is a transceiver

that converts both physical media and protocol. It translates RS-232 to

RS-485, and it goes from a normal electric cable to fiber optic. For this

reason, this box is connected to the RS-232 port of the computer.

At the other side of the fiber optic line, there is another transceiver

which receives RS-485 from the fiber optics and return RS-485 on normal

electrical signals. Inside the motor controller box, then, there are basically

three elements:

- Transceiver fiber-optic To cable (RS-485)

- Two PIC-STEP controllers, one for each filter wheel

The motor controller box is connected with the actual motor driver,

which in turn receives its power from the Pharo box. This motor driver

is connected to the WIRC wheel motors

Fig 2: motor controller connections

TCS communications

All the communications with the P200 TCS are done using the network

(RJ-45 ethernet port)